The hydraulic oil viscosity chart is essential when making oil choices. Everyone has felt the pressure and confusion when trying to pick the right hydraulic oil. Hence it’s vital to choose the right hydraulic oil as it is crucial for machines performance.

Viscosity refers to the ability of hydraulic fluid to resist flow. This is an important characteristic as it affects how your system operates. When the viscosity is high, it reduces efficiency. Alternatively, low viscosity may cause problems such as increased friction.

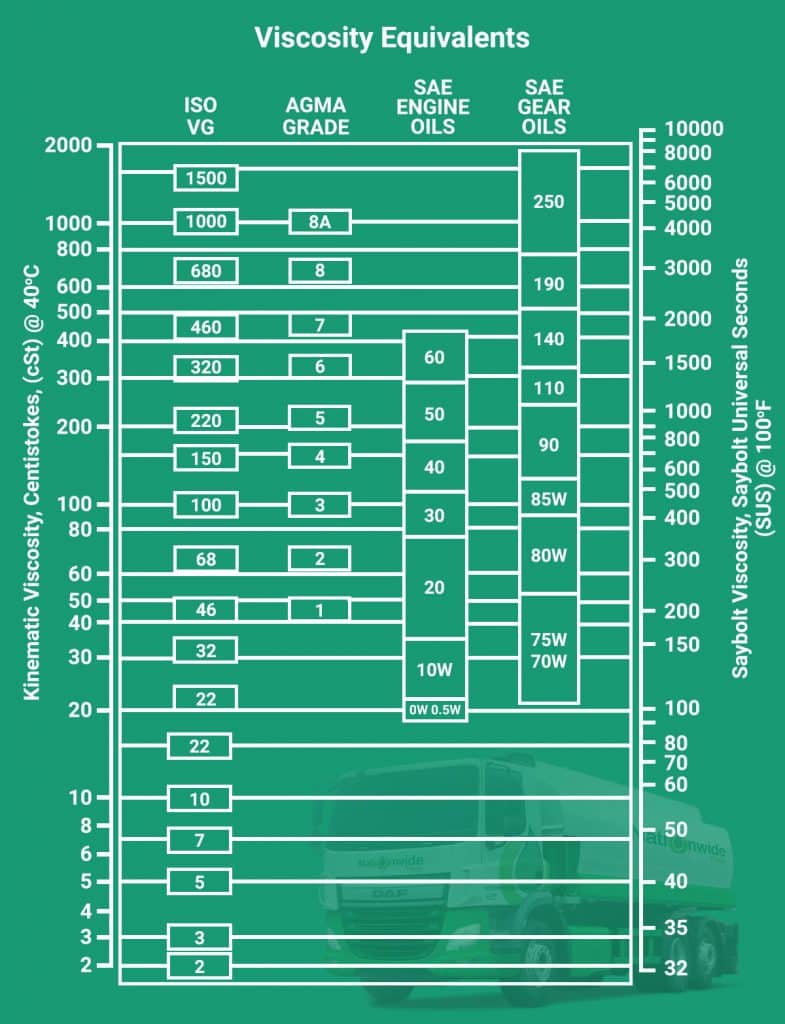

Thus, the viscosity chart is essential to help you make informed choices. This chart contains a list of oils and their respective viscosity. The chart has oils such as ISO VG, SAE engine oils, SAE Gear oils, and AGMA Grade. This article covers essential aspects of hydraulic oil viscosity, such as;

Chart Explained

International Organization for Standardization (ISO) is the commonly accepted measure for viscosity. The ISO Viscosity Grade (VG) applies if your application is stationary, whereas the SAE grade applies to a mobile application.

A lot of modern equipment falls into these two grades. Static gear boxes mostly match the American Gear Manufacturers Association ( AGMA).

The higher the VG number, the higher the viscosity, also called weight. Thus, grades that have W on them refer to the weight. However, W, next to automobile engine oil, refers to winter oil.

Viscosity grade gives you a hydraulic oil’s viscosity in centistokes (CST) at 400C . Most hydraulic systems apply a viscosity range of ISO VG15-ISO VG100. The chart below gives a reference point to help you convert between the four viscosity measures.

You can draw a horizontal line from your known viscosity chart across the hydraulic oil viscosity chart|. Those that you cross over are equivalents. It’s always important to check with your supplier, as some grades may cross over.

For example, SAE 90 covers ISO 150 to ISO 220. In application, ISO 150 works well in low temperatures, whereas ISO 220 works better in high temperatures.

Figure showing the hydraulic oil viscosity chart|

The different viscosity ranges have varying uses. This is as depicted in the table below;

| Hydraulic Oil Grade | Use |

| ISO 15 | -Hydraulic brake systems-Power Steering |

| ISO 22 | -Used in airlines |

| ISO 32 | -High-power machine tools |

| ISO 46 | -High-pressure industrial plants |

| ISO 68 | -Large load-carrying systems |

| ISO 100 | -Industrial machinery handling heavy load. |

How Viscosity Affects Performance

Working with low viscosity hydraulic oil increases the risk of internal leakage in your system. This, in turn, lowers efficiency. High viscosity fluids cause issues such as poor air release. Air release refers to how hydraulic oil releases enclosed air.

Hydraulic oils with more weight release air slowly compared to lighter oils. When air accumulates in the system, it may cause foaming. Thus, your equipment performs unpredictably since the pump takes in gulps of air with the oil.

When the hydraulic oils’ viscosity is higher than expected, you may experience cavitation problems. This is a low-pressure issue when the pressure in the pump is below the oil’s vapour pressure.

Bubbles and cavities form in the oil. This may cause lower lubrication, metal erosion, heat, and wear. When you use thicker oil, it is slower to pump, which increases the chances of cavitation.

To identify this problem, check for abnormal sounds such as knocking or banging. If your system requires high viscosity oils, you can incorporate varying-sized reservoirs. This provides more time for the air to escape.

Due to the resistance, valves and filters struggle to pass high-viscosity hydraulic oil. This may damage the system or increase the need for maintenance.

Low viscosity fluid will destroy your sealant, causing increased friction between the metal parts. This causes your system to wear faster. Wear and friction also generate heat, lowering the viscosity further. This causes thermal problems that ultimately shorten your machine’s life.

How to achieve the optimum hydraulic oil viscosity

Picking the suitable hydraulic oil grade is the most crucial factor when choosing your hydraulic oil. A significant condition that affects hydraulic oil viscosity is the temperature. The higher the temperature, the lighter the oil, and vice versa.

To make the right choice, you should consider the system’s operating temperature and recommended viscosity range. You may need higher viscosity hydraulic fluids when working in extreme temperatures.

You could also consider using Viscosity Index improver additives to manage viscosity changes. These improvers are helpful in extreme temperatures such as winter or summer. The molecule chain in the modifiers contract in low temperatures and relax in high temperatures.

In a contracted state, the molecules flow easily, while in a simple form, they reduce flow. This maintains optimum viscosity at all times. When choosing an improver for your system, check on the quality to ensure your system’s durability as well.

From the above discussion, it is clear that hydraulic oil viscosity is central to your system’s operation. The hydraulic oil viscosity chart is your best guide to avoiding mistakes. You can also refer to your system’s documentation for reference. Do not hesitate to contact your manufacturer or supplier for clarification when you are in doubt.